The Ladder Type Cable Trays SIESA® offer a reliable and secure solution for the management of electrical cables and instrumentation. Manufactured with plastic profiles reinforced by the pultrusion process, these trays are an outstanding choice to optimize the distribution and organization of cables in industrial and commercial environments.

Designed to withstand adverse weather conditions, our trays have exceptional resistance to ultraviolet rays, guaranteeing their durability over time.

Meeting the highest safety standards, our trays are non-combustible, with a flame spread index of 15, providing fire protection in critical environments.

Its lightweight design and simplified installation process allows for quick and efficient assembly, saving valuable time and resources.

The high quality of the materials used in the manufacture of our trays guarantees exceptional resistance to corrosion, maintaining its integrity in challenging environments

At SIESA®, we are committed to providing high-quality solutions that meet the most demanding safety and performance standards. Our Ladder Cable Trays are a reliable investment in optimizing cable management in a variety of applications, from offshore platforms to industrial and commercial settings. Experience the difference with SIESA® and take your electrical infrastructure to the next level.

Remember, we are here to help you optimize your facilities with cutting-edge products. Contact us today and find out how our Cable Trays can benefit your project!

Our pranks ladder type cable holder SIESA® They are an essential element in cable management in industrial and commercial environments. They stand out for their cutting-edge design and outstanding features that guarantee efficiency and safety.

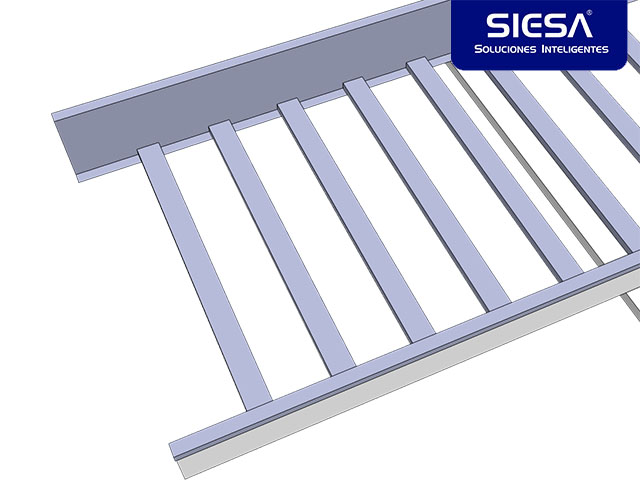

Our straight sections of SIESA® ladder type cable trays They are made of pultruded profiles of fiberglass-reinforced plastic. These sections, available in standard 4″ and 6″ cants, offer a versatile and durable solution for electrical cable distribution.

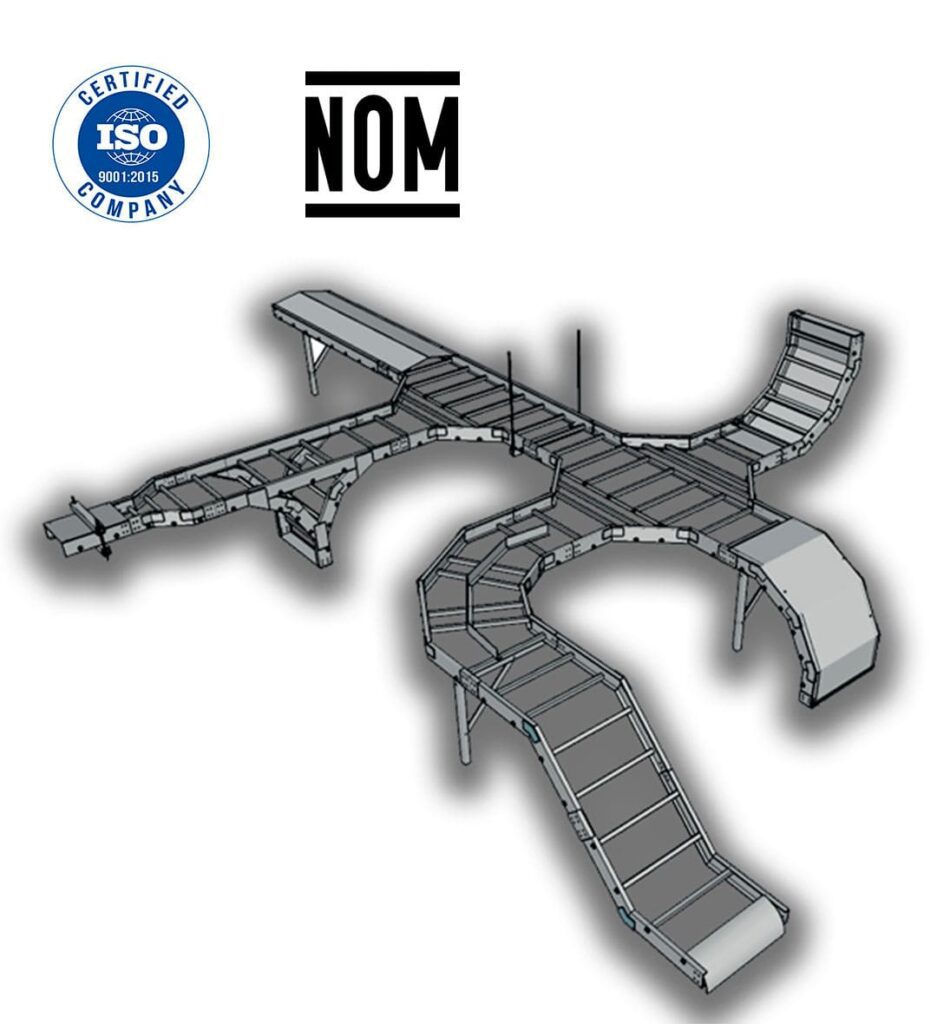

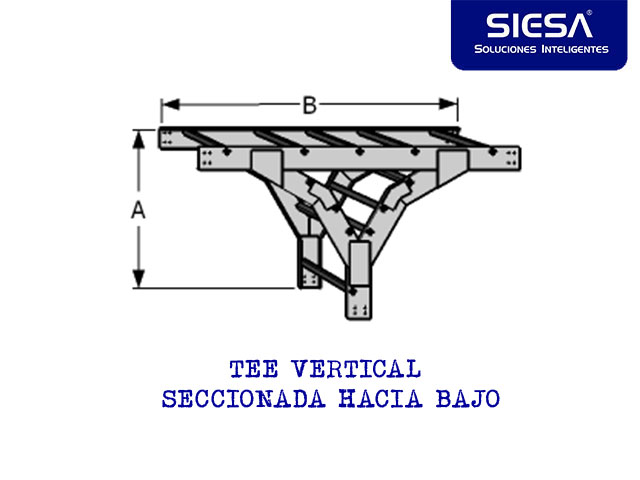

SIESA® FRP Ladder Tray Accessories They are a key piece to create efficient and well-organized cable support circuits.

At SIESA®, our priority is to provide you with high-quality, high-performance electrical solutions. Experience the difference in safety and efficiency with our ladder type cable trays. Contact us today and discover how to optimize your cable management with SIESA®!

The Fiberglass Cable Trays compared

with traditional steel trays on installation platforms to support electrical cables. Our fiberglass trays are 100% corrosion resistant and do not conduct electricity or generate static, making them an exceptional choice for demanding environments such as offshore platforms.

We have had the privilege of implementing our fiberglass cable tray system in the Leading Marina PP-TEKEL-A. This decision was made considering the environment

particularly challenging characterizing offshore platforms, where the handling of highly flammable products and safety in electrical management are of vital importance.

In these marine environments, corrosion is a ubiquitous problem, as the breeze is loaded with chlorides and other salts that significantly accelerate the corrosive process, especially in metallic materials such as steel or even aluminum. For this reason, opting for fiberglass cable trays is an essential preventative measure to ensure the integrity and durability of the electrical systems on the platform.

In addition to their corrosion resistance, fiber cable trays glass offer the additional advantage of being extremely light, lo which minimizes the total weight of the system. This characteristic is crucial for Ensure trays can support all cables of the engines of the marine platform without compromising its integrity structural nor its

operating efficiency.

Our cable trays are UL (Underwriters Laboratories) tested.

They comply with the NEMA FG1 STANDARD, resist high temperatures according to ASTM E84 with a flame spread index of 15 (Issued by Southwest Research Institute) and ASTM D635, SELF-EXTINGUISHING and FIRE RETARDANT.

SIESA ladder type cable trays® They are made from fiberglass reinforced plastic using pultruded profiles (polyester and vinylester), which have self-extinguishing and fire retardant properties.

To determine the dimensions of the cable trays, the following data is needed:

Founded in 1988 with the objective of helping the different branches of the industry to prevent and solve critical corrosion problems.

100% Mexican company, with vision for the future, dedicated to the supply of materials and engineering services to solve corrosion problems in industrial, residential and government processes.

SIESA | © 2023, All Rights Reserved | Use Policy

Site developed by: Fatuor Network